Little Known Facts About Uv Filtration.

Table of ContentsThe Basic Principles Of Uv Filtration Excitement About Uv FiltrationSome Known Factual Statements About Uv Filtration See This Report about Uv Filtration

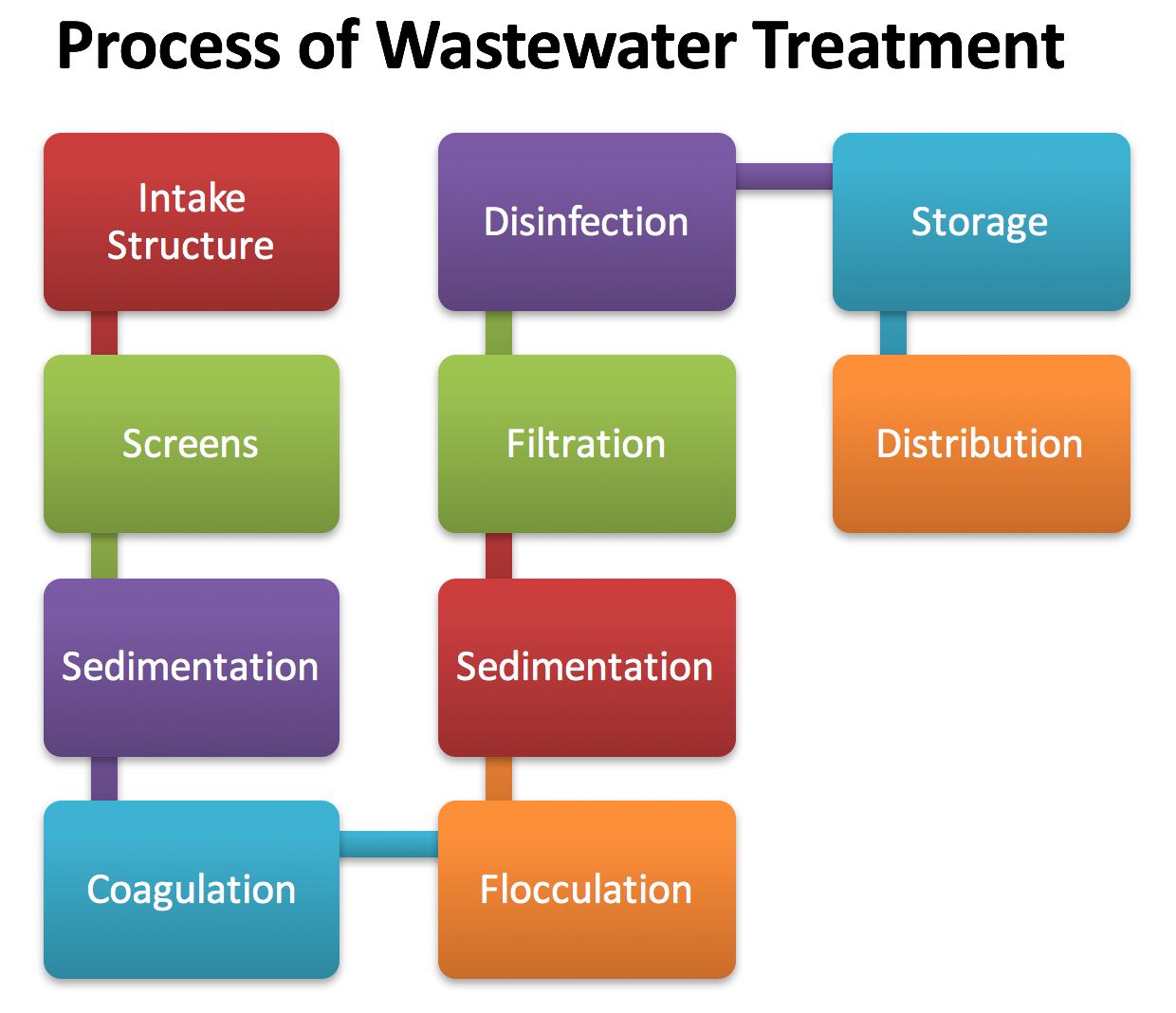

Removal of preference as well as odor substances from the water.: Softens the water.: Filtration to remove small bits and sanitation to kill infections as well as bacteria, as well as guarantee an unsuitable setting for virus and also bacteria development throughout the circulation system.

8 Stages of the Wastewater Refine Phase One Bar Screening Elimination of large products from the influent to stop damages to the center's pumps, valves as well as various other devices. The procedure of dealing with and recovering water from wastewater (any water that has actually been made use of in homes, such as flushing bathrooms, cleaning dishes, or bathing, as well as some water from commercial use as well as tornado sewers) begins with the expectation that after it is treated it will be tidy adequate to reenter the atmosphere.

Getting The Uv Filtration To Work

According to the EPA, The Tidy Water Act (CWA) develops the standard structure for controling discharges of contaminants right into the waters of the USA and also managing top quality standards for surface area waters. Under the CWA, EPA sets wastewater standards for sector. The EPA has likewise established national water quality criteria suggestions for pollutants in surface area waters.

Relevant White Documents Select Products Phase Two Screening Removal of grit by flowing the influent over/through a grit chamber. Great grit that locates its way right into the influent demands to be removed to avoid the damages of pumps and tools downstream (or influence water circulation). Also small to be evaluated out, this grit requires to be gotten rid of from the grit chamber.

Stage Four Oygenation Air is pumped right into the oygenation tank/basin to encourage conversion of NH3 to NO3 and also provide oxygen for bacteria to proceed to multiply and also grow. Once transformed to NO3, the microorganisms remove/strip oxygen particles from the nitrate molecules and also the nitrogen (N) is emitted as N2 (nitrogen gas) - uv filtration.

This begins in the oygenation tank. The key feature of the aeration container is to pump oxygen into the storage tank to urge the failure investigate this site of any kind of organic product (and also the growth of the bacteria), along with make certain there suffices time for the natural material to be damaged down.

The 8-Minute Rule for Uv Filtration

This process is handled to supply the very best problems for microbial growth. Oxygen gas [O2] levels listed below 2 ppm will kill off the microorganisms, minimizing performance of the plant. Dissolved oxygen surveillance at this stage of the plant is essential. Ammonia and nitrate measurements prevail to measure exactly how effective the microorganisms are in converting NH3 to N2.

Phase 5 Secondary Clarifier Treated wastewater is pumped into a secondary clarifier to enable any type of staying organic sediment to clear up out of treated water flow. As the influent exits the aeration process, it flows into a secondary clarifier where, like the main clarifier, any type of very little solids (or fines) sink to the base of the storage tank.

With the enhanced focus of bacteria as component of the oygenation stage, there is a need to check the outward bound effluent for microorganisms presence or lack and also to disinfect the water. This guarantees that greater than defined focus of bacteria are not launched right into the atmosphere. Chlorination is the most usual as well as inexpensive sort of disinfection but ozone and also UV disinfection are also increasing in appeal.

Uv Filtration Can Be Fun For Anyone

Water is directed from the Head Storage Tank to the Claricone clarifier. Water goes into the clarifier at the mixing zone located in the base of the Claricone - uv filtration. Lime is contributed to the water in this zone where it responds with the calcium as well as the magnesium in the water to form speeds up.

After sufficient time, fragments adhere to each various other and expand right into larger bits, or, floc, which is vulnerable to clear up in water. Clarification of water is these details achieved by the seperation of put on hold solids from water by gravity.

The clarified water steps upward slowly, at some point overlooking the effluent weir to the cone electrical outlet and on the to filters for further therapy. The water plant incorporates a solitary phase lime softening procedure to remove solidity. Hardness is triggered by the existence of dissolved bivalent and also polyvalent metal ions, mainly calcium as well as magnesium.

This is added both in the clearwell as well as the high service discharge as water goes into the distribution system. 2 mg/l is usually desirable in the plant tap.